| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : TISCO

Model Number : 200Series 300 Series 400 Series C276 904L,Monel 400 K500

Certification : ISO

Place of Origin : China

MOQ : 2 Ton

Price : 2400 - 3500 USD/Ton

Payment Terms : L/C, T/T, Western Union

Supply Ability : 20Ton per week

Delivery Time : 5 - 12 days based on the quantity

Packaging Details : standard packing for export

Products : stainless steel strip

Thickness : 0.03 - 3.0mm

Width : within 1500mm

MOQ : 1000 kgs

Grade : 200 series 300 series 400 series , nickel alloy

Surface : BA 2B NO.4 HL 8K NO.1

Standard : ASTM EN GB JIS

Packing : wooden frame and water proof paper

Specification of 301 Stainless Steel Strip

| ProductName: | 301 Stainless Steel Strip |

| Standard: | ASTM,AISI,DIN,EN,GB,JIS |

| Grade: | 201,301,304,310S,316,316L,430,409,410,434.etc |

| Thickness: | 0.1mm-3.0mm |

| Width: | 15mm-1500mm,or customized |

| Edge: | Slit edge/Mill edge |

| Surface: | 2B,BA,HL,Mirror,2D,NO.1 |

| Packaging: | Standard exporter package or as your requirements |

| Origin: | China |

| Supply Ability: | 50 Tons per Month |

| Price terms: | EX-Work,FOB,CIF,CFR,CNF |

| Payment terms: | T/T,30%advanced payment before production and balance before shipment; |

| MOQ: | 2 Ton each size |

| Delivery time: | 10-15 days after receiving deposit by T/T or L/C. |

| Sample: | Samples free and express charges bear by you. |

AISI 301 stainless steel (UNS S30100) is the most susceptible to cold deformation strengthening among conventional austenitic stainless steels. Its work hardening rate is extremely high, with each increase in the amount of cold work, the tensile strength and yield strength will increase significantly. The response to work hardening is particularly important for structural parts, including angle steel and channel sections, which are expected to have additional strength and stiffness after manufacture. On the other hand, for deep drawing applications, lower work hardening rates are generally preferred and can be obtained in austenitic alloys with higher nickel content (especially types 304, 304L, and 305).

Chemical Composition of 301 Stainless Steel

| AISI (UNS) | C, ≤ | Si, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | Ni | Mo, ≤ | Cu, ≤ | N, ≤ |

| 301 (UNS S30100) | 0.15 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 6.0-8.0 | – | – | 0.1 |

| 18Cr-8Ni (SAE 30301) | 0.15 | 1.00 | 2.00 | 0.040 | 0.03 | 16.0-18.0 | 6.0-8.0 | 0.75 | 0.75 | – |

Type 301 stainless steel properties

| Type 301 Mechanical Properties | |||||||

| ASTM | AISI Type (UNS) | Conditions | Tensile Strength, MPa (ksi), ≥ | 0.2% Yield Strength, MPa (ksi), ≥ | Elongation in 50 mm (2 in.), %, ≥ | Brinell Hardness (HB), ≤ | Rockwell Hardness (HRB), ≤ |

| ASTM A666 | 301 (UNS S30100) | Annealed | 517 (75) | 205 (30) | 40 | 217 | 95 |

| Full Hard | 1275 (185) | 965 (140) | 8 (<0.015 in.); 9 (≥ 0.015 in) | ||||

| Super Full Hard | 1860 (270) | 1790 (260) | – | ||||

| Half Hard | 1035 (150) | 760 (110) | 15 (<0.015 in); 18 (≥ 0.015 in) | ||||

| 3/4 Hard | 1205 (175) | 930 (135) | 10 (<0.015 in); 12 (≥ 0.015 in) | ||||

| 1/4 (quarter-hard) Hard | 862 (125) | 517 (75) | 25 | ||||

| 1/8 Hard | 690 (100) | 380 (55) | 40 | ||||

| 1/16 Hard | 620 (90) | 310 (45) | 40 | ||||

| SAE AMS 5517 | 18Cr-8Ni (SAE 30301 ) | – | 862 (125) | 517 (75) | 25 | 252, ≥ | 25 HRC, ≥ |

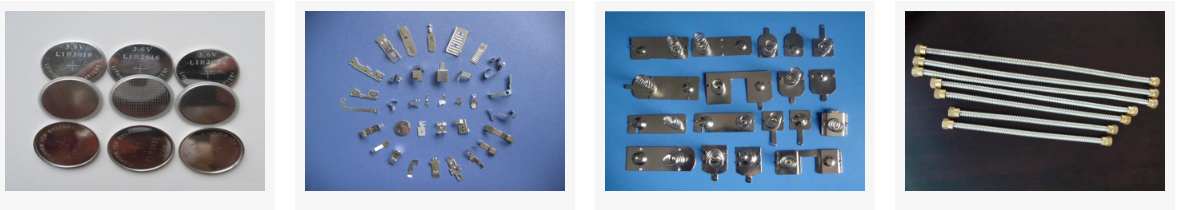

Type 301 have been extensively used in coining of spoons and forks, other applications include springs, fasteners, clamps, automotive wheel covers, aircraft structural parts, etc.

Products Picture

|

|

AISI301 Precision Stainless Steel Strip 1/4H 1/2H 3/4H FH Thickness 0.03 - 3.0mm Images |